| Name: | DDG-2090 industrial online conductivity meter |

|---|---|

| Measuring range: | 1.0~20.00uS/cm(K=0.01) 0~200.0uS/cm(K=0.1) 0~2000uS/cm(K=1) 0~20.00mS/cm(K=10) 0~600mS/cm(K=30) |

| Resolution: | 0.01uS/cm |

| Accuracy: | ±2.0%F.S. |

| Temperature compensation: | 0~100℃ NTC 10K (auto) |

| Output: | 4~20mA |

| Communication interface: | RS-485(optional) |

| Power supply: | AC220V±10% 50/60Hz |

1.Measuring range: 0.1~200 uS/cm (Electrode: K=0.1)

1.0~2000 us/cm (Electrode: K=1.0)

10~20000 uS/cm (Electrode: K=10.0)

0~19.99MΩ (Electrode: K=0.01)

2. Resolution: 0.01 uS /cm, 0.01 MΩ

3. Precision: 0.02 uS /cm, 0.01 MΩ

4. Stability: ≤0.04 uS/cm 24h; ≤0.02 MΩ/24h

5. Standard solution: Any standard solution

6. Control range: 0~19.99mS/cm, 0~19.99KΩ

7. Temperature compensation: 0~60.0℃

8. Output signal: 4~20mA isolated protection output, Can double the current output.

9. Output control mode: ON/OFF relay output contacts (two sets)

10. Relay load: Max. 230V, 5A(AC); Min. l l5V, 10A(AC)

11. Current output load: Max. 500Ω

12. Working voltage: AC 230V ±l0%, 50/60Hz

13. Overall dimension: 96x96x110mm; dimension of the hole: 92x92mm

14. Working condition: ambient temperature: 5~45℃

DDG-2090 series of microcomputer-based industrial control instruments are precision meters for measurement of conductivity or resistivity of solution. With complete functions, stable performance, simple operation and other advantages, they are optimal instruments for industrial measurement and control.

The advantages of this instrument include: LCD display with back light and display of errors; automatic temperature compensation; isolated 4~20mA current output; dual relay control; adjustable delay; alarming with upper and lower thresholds; power-down memory and over ten years of data storage without backup battery.

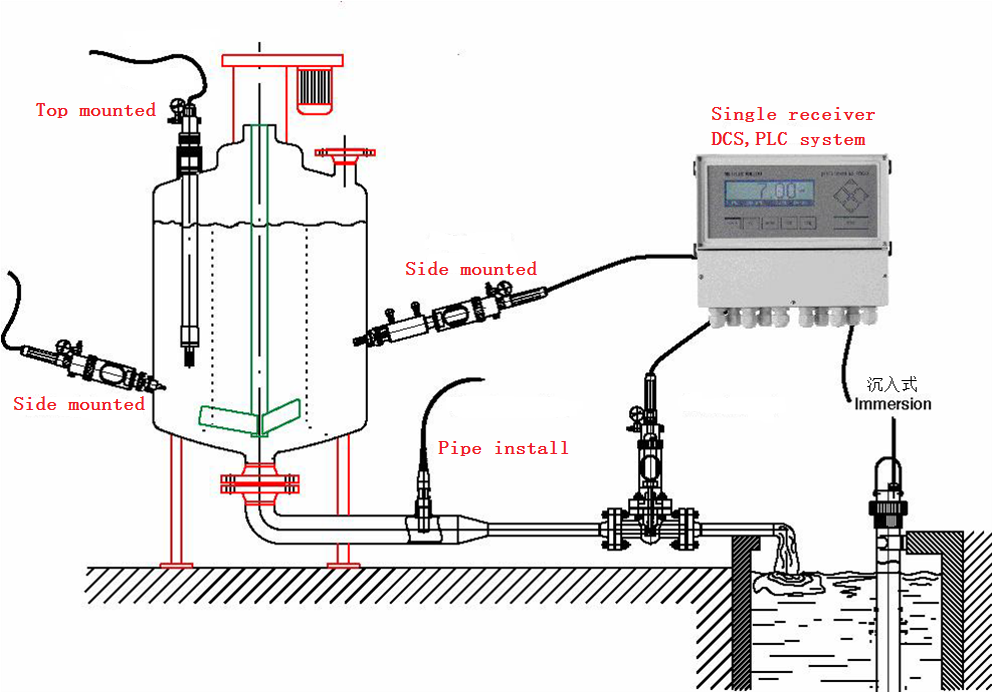

According to the range of resistivity of the water sample measured, the electrode with a constant k = 0.01, 0.1, 1.0 or 10 can be used by means of flow-through, immerged, flanged or pipe-based installation.

DDG-2090 Industrial online Conductivity Meter is developed on the basis of guaranteeing the performance and the functions. The clear display, simple operation and high measuring performance provide it with high cost performance. It can be widely used for continuous monitoring of conductivity of water and solution in thermal power plants, chemical fertilizer, metallurgy, environmental protection, pharmacy, biochemical engineering, foodstuff, running water and many other industries.

Sewage treatment

Aquaculture

Circulating water treatment

Dosing control

Biopharmaceutical

Fermentation

Chemical Industry

Power plant

Influent water treatment

Pretreat influent water before it enters your plant’s system. Proper influent water monitoring is the first defense to protecting the health of your equipment and preventing corrosion. By properly treating water at this stage, you can reduce costs and treatment within the power and steam generating process.

Steam and power generation

Protect your equipment – from pipes and tubes, to turbines and boilers – by ensuring your water is of the highest quality. Minimize silica levels to prevent turbine blade erosion, and monitor and manage dissolved oxygen (DO) to prevent corrosion.

Cooling water

Ensure heat transfer processes are as efficient as possible by effectively controlling total suspended solids (TSS) to avoid the expense and downtime associated with fouling and mineral buildup that can cause scaling and hazardous operating conditions.

Industrial wastewater

Ensure compliance with all discharge requirements. Our industrial wastewater solutions help you minimize environmental impact and ensure compliance with permits.